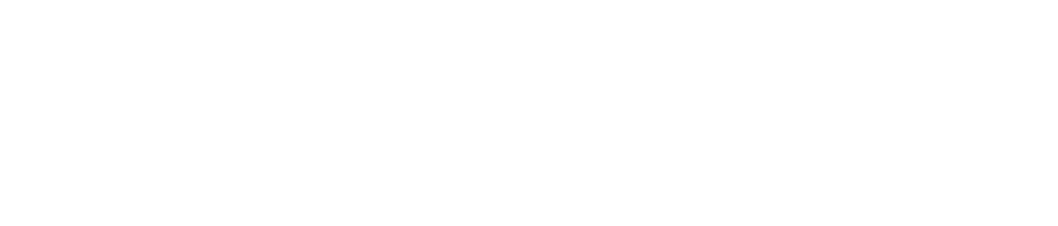

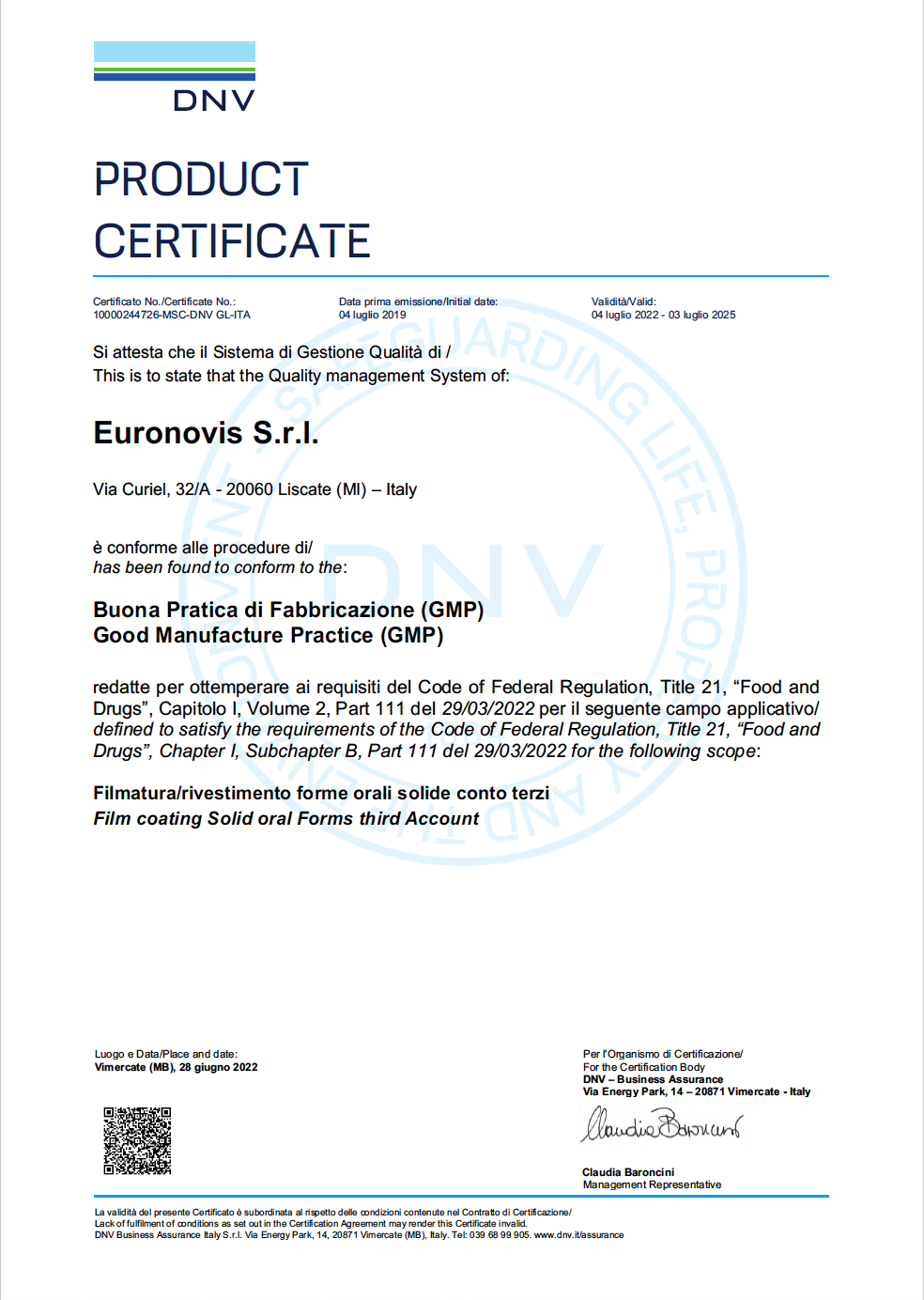

CERTIFIED QUALITY

When it’s about quality and controls, we at Euronovis never leave anything to chance: from prime matters to cleaning, from team formation to equipment and systems check, for us it is of absolute priority that everything ensures the maximum safety and quality for the final result.

Procedures

All performed operations are finely regulated by HACCP and GMP norms. Prime matters, tools and semi-finished products (incoming and outgoing) are stocked in specific warehouseson; temperature and hunmidity are constantly monitored inside the whole laboratory.

PRIME MATTERS

All prime matters, purchased by certified suppliers, are sampled, labeled and stocked in suitable warehousesi. periodically, we perform analysis in authorized laboratories to determine the grade of purity and check the conformity of the parameters shown in CoA.

SAFETY AND TRACEABILITY

Each operative phase (from product reception, through productive and preparation phases, to semi-finished products packaging) is performed by following meticulous internal procedures, in order to ensure to the client safety, uniformity and traceability for each single processing.

CLEANING

The staff meticulously follows appropriate operative instructions, is constantly updated on the current normative and is equipped with suited and dedicated PPEs. the facility is periodically cleaned and sanified, just like the boxes after each processing.

WATER RESOURCES MANAGEMENT

The water used for the preparation fo the solutions is periodically analyzed and, on request, the use of F.U. Puriifed Water is available.

MAINTENANCE

An inside maintainers team checks and ensures the correct functioning of all systems following pre-determined quality standards. On the basis of a programmed planning, each system is refgularly calibrated and prior ispectioned before each processing.

Discover our lab’s systems

Discover the structure of our cleanroom