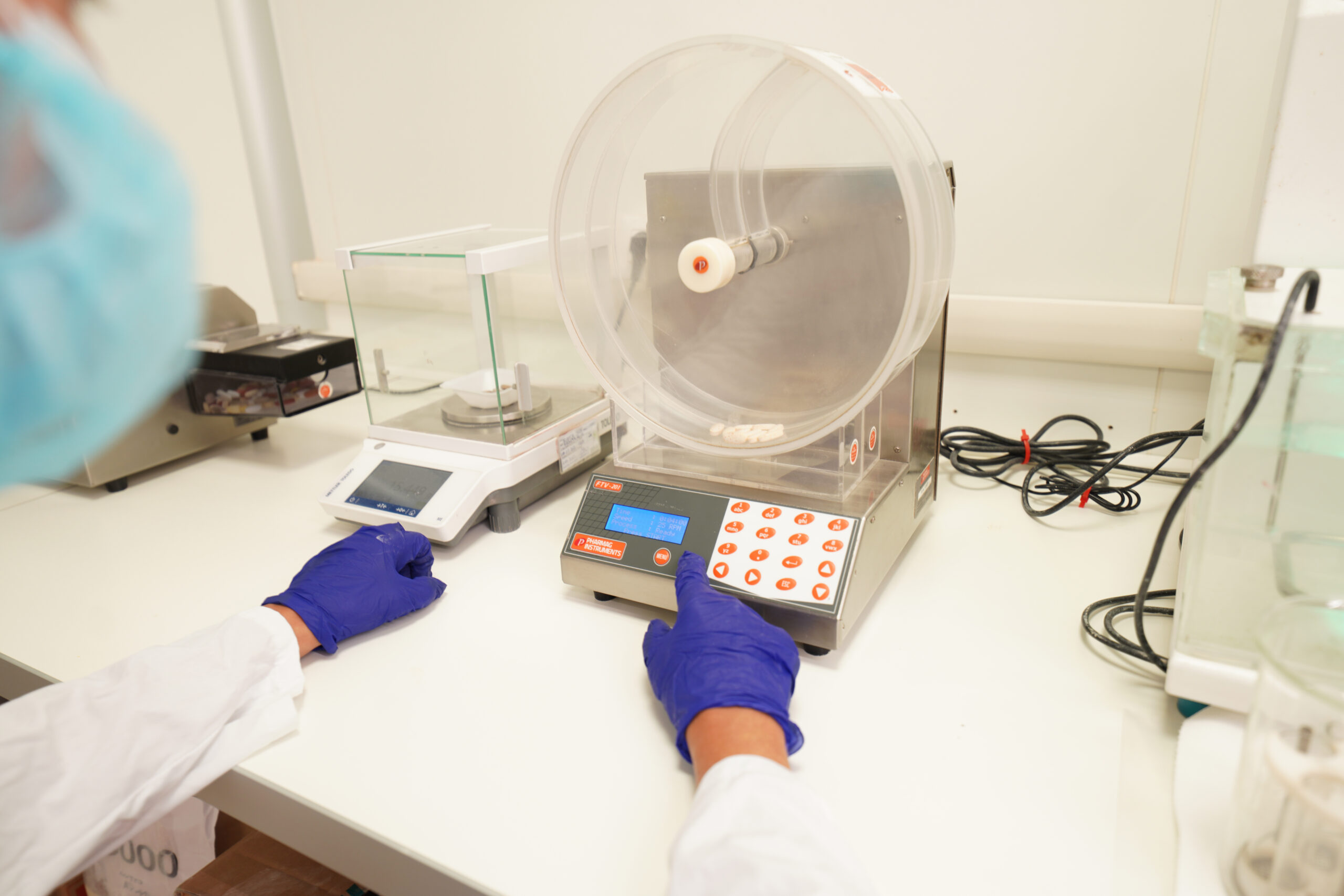

The production site

All the production chain processes, from receiving materials to reteasing fìnished products, are performed in our operating office just a few minutes from Milan Linate airport. The types of wall, ceiling, fittings, floors and fìnishing, all certifìed Nicomac Europe, are the same as those used by the pharmaceutical sector. The air fìltering and conditioning systems guarantee environmental overpressure and perfect control of internal thermo-hygrometric conditions. The technical room, created with a specifìc gallery overlooking the cleanroom, is dedicated to all utilities serving the latter and the processing plants. Three 200,000 Kw/each boilers and three 30 Kw/each air compressors have been installed on the outside.

Inside the lab is:

Locker room

Dispensing

Quality control room

Coating boxes

Granulation area

Solution preparation room

Washing room

R&D

Warehouses

The cleanroom is also equipped with:

air treatment unit

pressure monitoring

temperature monitoring

hunmidity monitoring

solvent presence monitoring

ventilation hood

Discover the technologies of our lab

Discover Nicomac Europe cleanrooms