Pharmaceutical technology

Here, you can find in-depth articles on pharmaceutical and nutraceutical production, including detailed insights on processes, technologies, and innovations in the industry. Every article is curated by Euronovis’ technical experts, sharing their knowledge, best practices, and advanced solutions to optimize production processes and ensure high-quality standards.

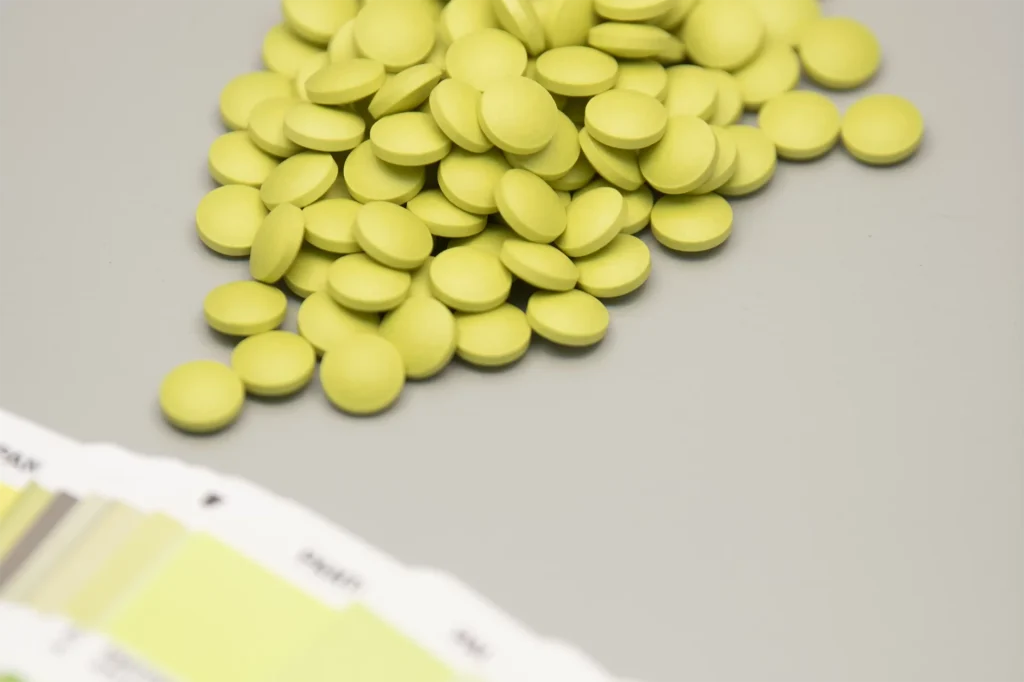

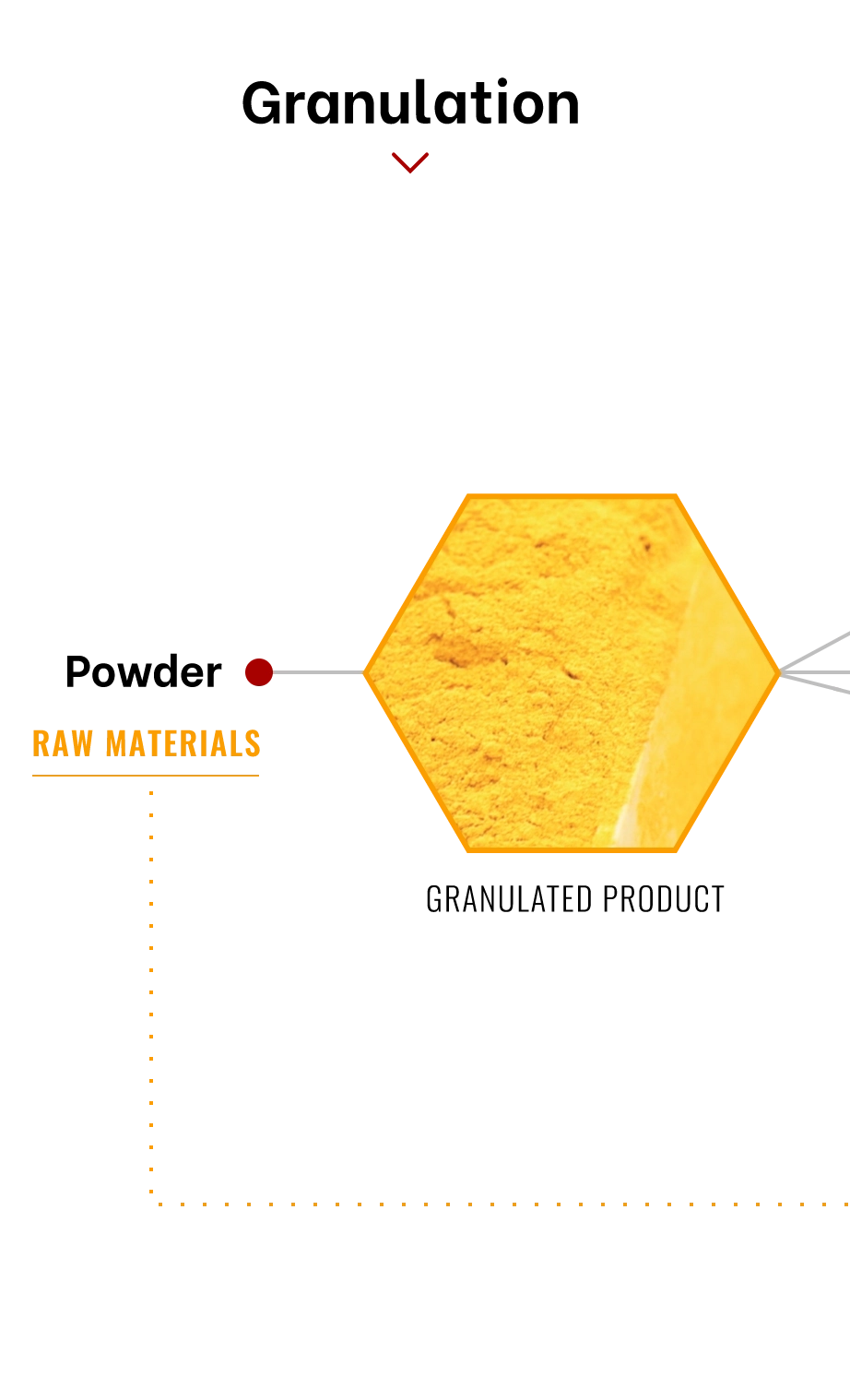

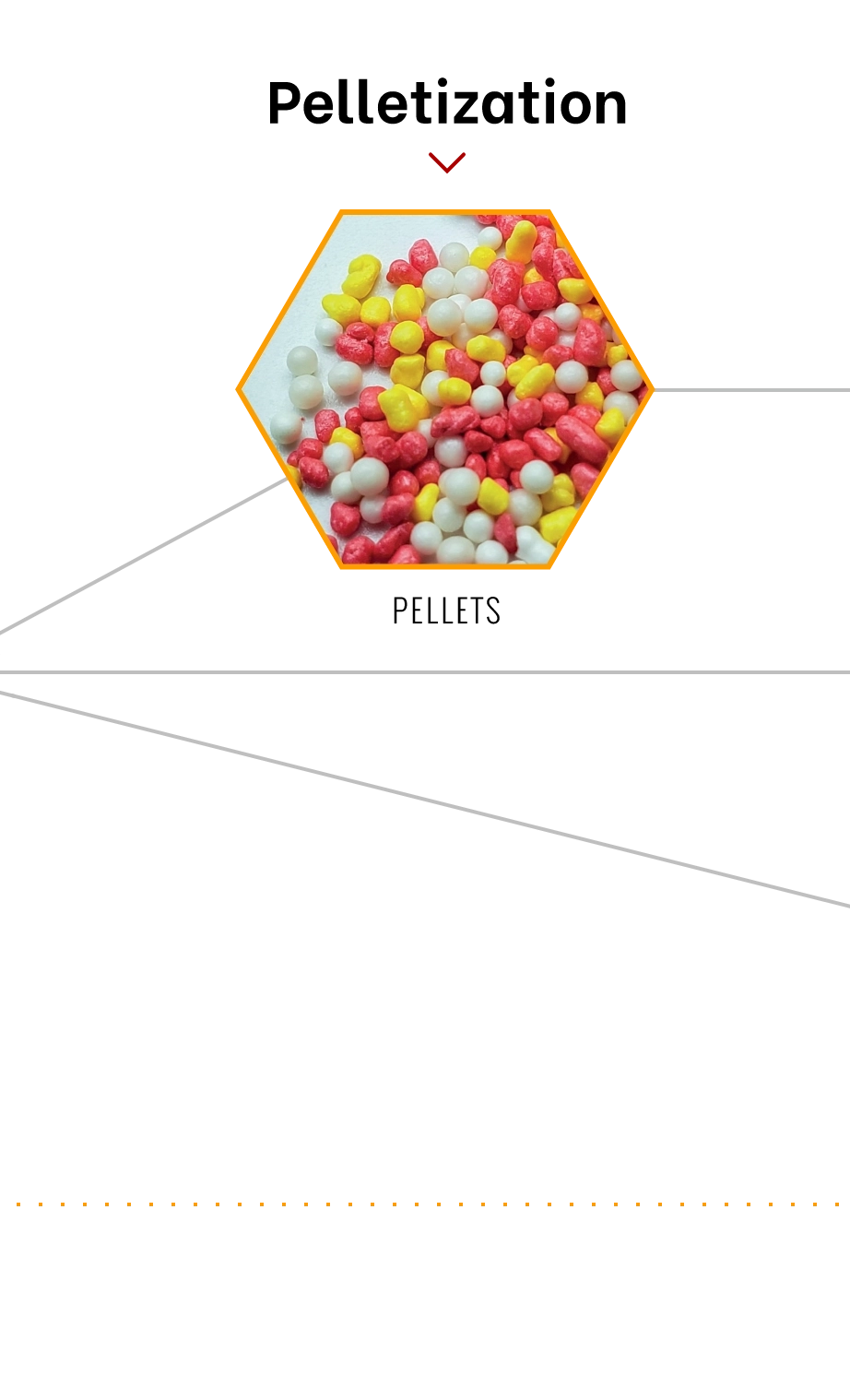

Read allPelletization in the Nutraceutical Sector

What is pelletization? How are pellets produced? What advantages do they offer as an oral solid dosage form for dietary supplements?

+